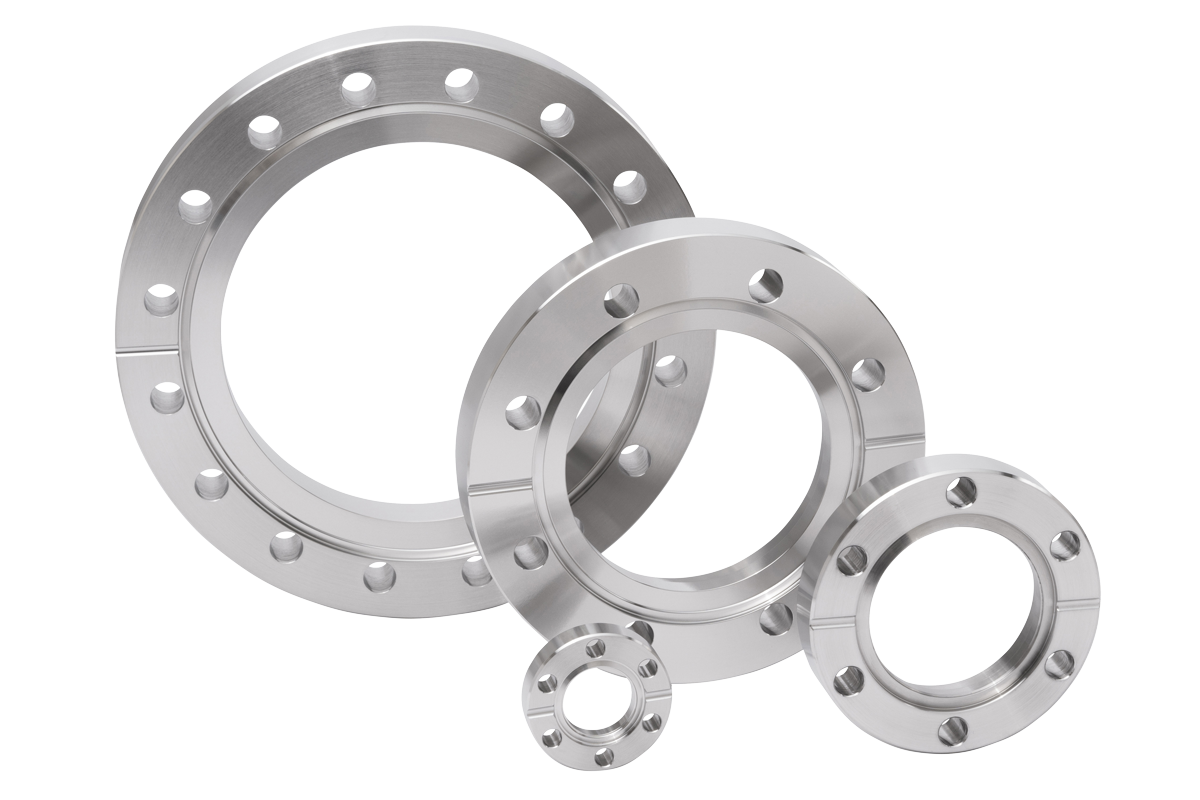

Highest quality vacuum parts & chambers, delivered on time.

*Specialists in high & ultra high vacuum

*Quick and easy online shop

*Customer service team ready to take your enquiry

Please make your purchases out to UltraHighVacuum.com & email to [email protected]

Please read our press release for more information